Modern vehicles’ overlooked heroes are their car batteries, which supply the energy required to run different electronic devices and start motors. However, just like any component, their performance can decline over time, which raises the following typical query: Can a car battery test good and still be bad?

Yes, a car battery can test good but still be bad. Testing methods often focus on voltage, overlooking factors like diminished cold cranking amps and internal degradation that affect performance.

In this comprehensive exploration, we delve into the intricacies of battery testing, the challenges of changing weather conditions, and the complexities of interpreting test results.

Table of Contents

Understanding Car Battery Testing:

Testing a car battery often involves several techniques, such as a load or voltage test. These tests determine whether the battery can supply enough electrical power to start the engine and run the car’s systems. Testing a car battery typically entails determining its voltage and amperage capacity.

The battery’s capacity to produce electricity is shown by amperage (current), while the battery’s stored energy is represented by voltage.

While a battery’s voltage may sound reassuring, it is not the only factor determining how well it will work. A seemingly “good” test result might not reflect the battery’s actual condition, even though these tests are typically trustworthy predictors of a battery’s health.

Why Does Car Battery Test Good And Still Be Bad?

1. Cold-Cranking Amps (CCA):

The number of cold cranking amps (CCA) a battery has will determine how well it can start an engine in cold weather. A battery may test “good” based on voltage. Still, if its CCA is reduced because of wear or internal problems, it may not produce enough power during startup, resulting in a battery that appears “good” but doesn’t perform well in actual use.

2. Surface Charge Effect:

The surface charge effect is one typical factor contributing to a falsely “good” test result. An automobile battery may show a higher voltage reading than its actual charge level if it has just been charged or been connected to a charger.

This brief increase in voltage may produce a misleading test result, giving the impression that the battery is healthier than it is. The battery’s actual state can be seen when the surface charge has dissipated.

3. Intermittent Faults:

Intermittent defects in car batteries can arise from problems including internal cell degradation, sulfation, or faulty connections. The performance of the battery may change as a result of these issues.

If the battery is temporarily performing better while being tested, it can produce a favorable outcome. But when the problems persist over time, the battery’s dependability declines.

4. Underlying Internal Issues:

Testing might not always reveal all internal battery issues, such as corroded or cracked plates. Even if the initial test yields positive results, these problems may affect the battery’s capacity to maintain a charge and produce steady power. The battery’s performance will deteriorate as these issues worsen, possibly leaving you stranded.

5. Temperature And Load Dependency:

External variables like temperature and the amount of electricity used by the car might have an impact on the functioning of the battery.

When temperatures are extremely high or the electrical demand on the vehicle is considerable, a battery that operates well in moderate settings and under light loads may find it challenging to provide enough power. Testing under ideal circumstances might not show these restrictions.

6. Aging And Wear:

Batteries lose some of their ability to store and transfer electricity as they age. Even if a battery’s total capacity has decreased, it may still produce acceptable test results. It implies it might struggle in circumstances requiring extended power or repeated starts.

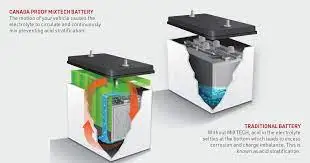

7. The Acid Stratification Challenge:

One of the primary reasons a battery can have a suitable voltage yet be unreliable is due to a phenomenon called acid stratification.

It occurs when one or more cells or plates within the battery become damaged, impairing its ability to hold a charge and deliver consistent amperage. Acid stratification can falsely inflate voltage readings during testing, leading to deceptive results.

The Need For Load Testing:

Load testing is necessary to evaluate a battery’s condition accurately. Load testing replicates real-world situations by placing a high electrical load on the battery to match the demands made on it during vehicle startup and operation.

A battery may have a high voltage while unloaded but not be able to maintain it under load. A clearer view of the battery’s performance is provided through load testing, which aids in identifying this disparity.

You Might Be Driving With A Dead Car Battery. Get A Battery Test:

Consider this: Your battery might be close to failing, like a glass with a concealed crack retaining water, even if it shows 75% or even 100% charge. A fully charged battery may not be able to store energy if it is too weakened and aged. The truth is that your automobile won’t start, regardless of the mild weather or usual driving.

A car battery must be tested in more ways than one, beyond a visual inspection. Conductance battery testers are used in the most accurate tests, which send a signal through the battery to determine its electrical conductivity.

Resistance hints at unacknowledged vulnerability. A load tester is another typical test, although you might not have access to one. You can use a multimeter or hydrometer for basic testing:

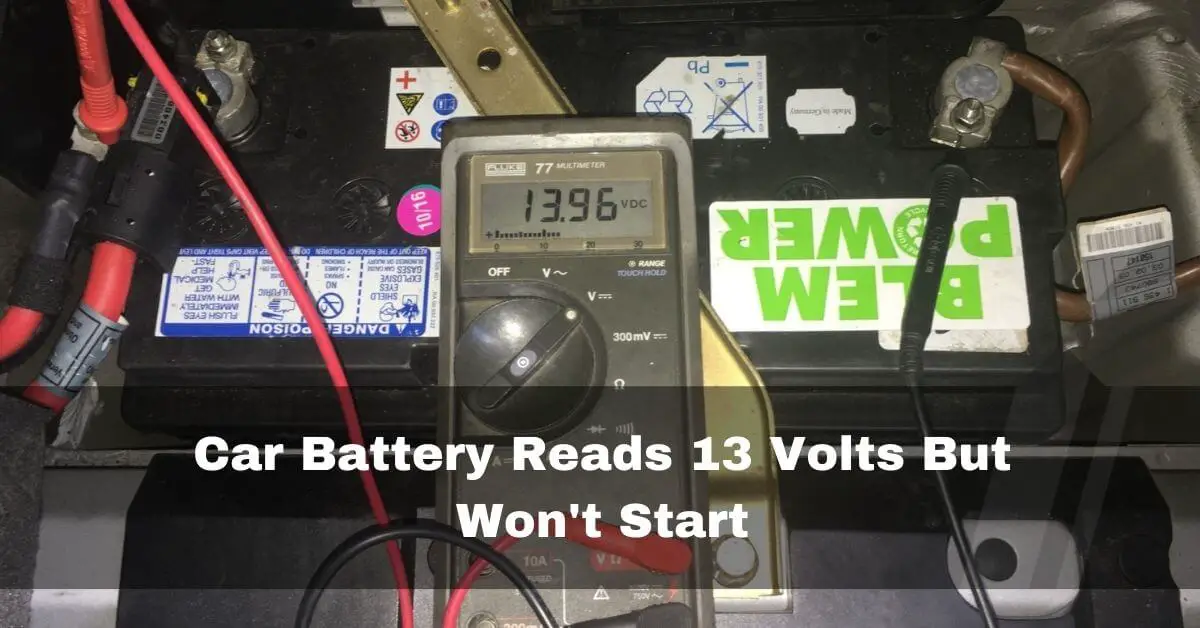

1. Multimeter Test:

- Let the headlights run briefly to remove the surface charge.

- Set the multimeter to a DC voltage above 15 volts.

- Connect the multimeter to the battery terminals.

- Check the voltage against this chart:

- 12.88V: 100% charge

- 12.64V: 75% charge

- 12.39V: 50% charge

- 12.09V: 25% charge

- 11.80V: 0% charge

2. Hydrometer Test:

- Use the headlight trick to remove the surface charge.

- Open the battery vent caps and insert the hydrometer’s nozzle into the electrolyte.

- Squeeze the bulb to draw a sample onto the hydrometer’s scale.

- Compare the hydrometer’s specific gravity readings to this chart:

- 1.300: 100% charge

- 1.255: 75% charge

- 1.215: 50% charge

- 1.180: 25% charge

- 1.160: 0% charge

Remember that these tests only reveal the battery’s charge levels, not its overall health. Conductance testers offer a more detailed study, whereas load testers are comprehensive but need special equipment. Take into account hiring a professional battery tester for trustworthy results.

Good or Replace? Testing Today’s Batteries With A Deeper Analysis:

A battery’s condition test is essential for making wise judgments. One technique is load testing, in which the battery is subjected to a calibrated load for 15 seconds.

When the battery voltage exceeds 9.6 volts, it is deemed “good.” Before correct results may be achieved from this test, the battery must be charged entirely (above 12.45 volts).

Alternatively, portable electronic load testers measure the reaction after applying a modest amp load to determine the battery’s condition. Since they don’t need a full charge, these testers are helpful for partially charged batteries.

1. Load Testing: Revealing the Strength of Your Battery:

The best way to evaluate your car’s battery’s true strength and condition is through load testing. Load testing explores the battery’s capacity to deliver power in actual situations instead of simple voltage checks. Let’s go on a journey to reveal the load testing procedure and its importance in comprehending battery performance.

Step 1: Understanding Load Testing:

In load testing, the battery is put under a controlled load to simulate the demands made on it during engine startup. We learn more about the battery’s capacity and condition by seeing how well it responds to this load.

Step 2: Gather the Necessary Equipment:

A tool made especially for load testing, an adjustable carbon pile battery tester, is required. Using this apparatus, you can load the battery with a calibrated load and observe how it responds.

Step 3: Set the Load:

The amount of load used during testing is crucial. It is usually set to the battery’s Cold Cranking Amps (CCA) value, which is half. The stress the battery undergoes during cold starts is reflected in this load level.

Step 4: Conduct the Test:

- Make sure the car is in a secure, well-ventilated location.

- Connect the battery terminals of the carbon pile tester. The tester’s positive lead should be connected to the positive terminal’s negative lead, and vice versa.

- Half the battery’s CCA rating should be the load setting on the tester.

- Start the test by turning on the load application for the tester.

- Throughout the 15-second load application, monitor the battery’s voltage.

Step 5: Interpreting the Results:

The voltage response of the battery during the load application offers essential information:

The battery is deemed “good” if the voltage stays above 9.6 volts. It has proven to manage the load without suffering a significant voltage loss.

By the end of the test, if the voltage is below 9.6 volts, it can be a sign of a “bad” battery. It’s crucial to remember that for accurate results, the battery may need to be recharged and tested again if it wasn’t fully charged before the test.

Step 6: Recognizing its Limitations:

Although load testing is a valuable technique, it is possible. One restriction is that, for reliable testing results, the battery must be at or above 12.45 volts (75% charged). Additionally, performing numerous load tests on the same battery may deplete it.

2. Conductance Testing: Unveiling Battery Health:

Conductance testing is a cutting-edge and reliable technique for evaluating the condition of a car battery. The battery’s ability to carry electrical current is measured using this technique, which provides essential information about the battery’s internal health. Let’s examine the procedures for carrying out an exhaustive conductivity test.

Step 1: Grasp the Concept of Conductance Testing:

The focus of conductance testing is measuring the battery’s ability to conduct an electrical current. The conductivity of batteries changes as they get older or develop flaws, signaling possible issues.

Step 2: Equip Yourself:

A conductivity tester made specifically for battery analysis is required. Modern conductance testers offer precise readings and can test batteries even when they are low on charge or almost totally depleted.

Step 3: Battery Preparation:

Make sure the battery’s terminals are tidy and secure before testing. Clean the posts or side terminals if necessary to provide a dependable connection.

Step 4: Perform the Conductance Test:

- Start by shutting off the engine and all electrical equipment in the car.

- As you attach the conductance tester to the battery terminals, ensure the connection is solid and appropriate.

- Start the test by following the manufacturer’s instructions. A low-frequency alternating current will be passed through the battery by the tester.

- The tester will measure the battery’s conductance, and readings indicating its condition will be provided.

Step 5: Analyze the Results:

How to interpret the conductance test’s results:

- High conductance: A high value indicates that the battery is strong and in good shape.

- Low conductance: A low conductance could point to battery deterioration, flaws, or other problems.

Step 6: Additional Features:

Some conductance testers offer extra features:

- CCA Capacity: Based on the battery’s Cold Cranking Amps (CCA) capacity, its remaining useful life is estimated.

- Measurement of Starter Amps: They count the amps the starter uses to turn the engine over.

- Analysis of the Charging System: After starting the engine, they examine the charging system’s output under load.

Step 7: Diagnosing Ground Connections:

Using conductance testers, you can identify poor ground connections. CCA tests should be performed at the battery terminals and again at a ground point on the engine or anywhere else. A significant disparity in the CCA measurements indicates poor ground.

Step 8: Making Informed Decisions:

Testing for conductance provides a precise picture of your battery’s condition. With this information, you can prevent problems, replace batteries as necessary, and guarantee dependable vehicle performance.

3. Key-Off Current Drains:

A key-off current drain that depletes the battery’s reserve power may be to blame when a vehicle’s battery often declines while passing battery and charging system testing. Less than 50 milliamps of parasitic drain should be present 1 hour after the car is stopped.

Fuses and relays can be removed once the current measurement decreases to locate the draining circuit. However, prudence is suggested due to the need for specialist handling of some components.

Testing AGM Batteries:

Auto manufacturers are progressively adopting Absorbed Glass Mat (AGM) batteries as the standard for many new vehicles in response to tightening fuel economy and emission rules.

AGM batteries, in contrast to conventional flooded-cell technology, have an electrolyte within a fibrous glass mat between the battery plates.

Due to the sealed structure of AGM batteries, however, this progression also brings a new testing strategy. Let’s examine the testing landscape for AGM batteries to identify effective and ineffective techniques.

1. Embracing Conductance Testing:

Conductance testing stands out as a solid option when these factors are considered. To measure the resistance of the battery plates using this method, a low-voltage alternating current is passed through the battery. Its accuracy in testing discharged batteries is beneficial.

In the past, conductance testers relied on the Cold Cranking Amp (CCA) value, which had drawbacks if the battery label was broken or illegible. Recent versions of conductance-type battery testers, though, get around this problem.

They don’t require CCA specification input, allowing for proper testing of AGM and gel-cell batteries and highlighting the significance of maintaining access to the most recent testing technology.

2. The 3-Minute Battery Test: Unveiling Battery Health:

Key insights are revealed by the standard 3-minute battery test, which charges the battery at a rate of 30 to 40 amps. If the charging voltage exceeds 15.5 volts, this indicates severe sulfation and the battery is probably beyond repair.

Incorporating an automatic “diagnostic charging” mode that tracks charging amperage and voltage is a common feature of contemporary battery chargers. The charger will advise replacement if deviations are from the recommended charging rate.

3. Securing Battery Vigor: A Rewarding Endeavor:

Knowledge enables us to ensure battery health in AGM battery testing. We pave the way for maintaining optimal battery performance by adopting conductance testing and comprehending the consequences of the 3-minute battery test. Adapting testing techniques becomes essential when AGM batteries become the standard, acting as an investment in the future.

Let’s proceed, armed with powerful testing techniques, with AGM batteries leading the automobile charge, to realize the full potential of these cutting-edge power sources.

FAQs:

1. Why Does My Car Battery Test Good But Keep Dying?

Loose or corroded battery connections, chronic electrical drains, charging issues, continuously consuming more power than the alternator can supply, and even extreme weather are some of the most typical causes of recurrent automobile battery failures.

2. Can A Battery Test Good But Not Hold A Charge?

Yes, it must be adequately cycled and loaded. You can’t just use a multimeter or other measurement tool to check the voltage and assume that 12 volts is good.

3. Can A Car Battery Show 12.5 Volts And Still Be Bad?

Your battery is in good condition, but we advise rechecking it in a few days to ensure the voltage has stayed the same. Your battery is partially depleted at 12.1 to 12.4 volts and must be recharged using an appropriate battery charger as soon as possible.

Conclusion:

When it comes to automotive batteries, appearances can be deceiving. A battery may seem in good condition—showing suitable voltage and passing routine tests—but conceal flaws that cause unforeseen problems. Our investigation of testing techniques reveals the limitations of depending only on voltage readings. Capacity and Cold Cranking Amps (CCA) are crucial, even in batteries that “pass.” Adopt a rigorous approach, combine conductance and load testing, and understand the nuances of batteries to avoid these errors. Depth is more important than surface when it comes to safe road excursions.